Nanobubbles:The Future

Nanobubbles are less than 1 µm in diameter. Due to its extraordinary chemical and physical characteristics, they have the potential to revolutionize the way of delivering drugs.

Ultra-fine bubbles (nanobubbles) are so small that they cannot be visualized even with the finest optical microscopes. Ultra-fine bubbles are different from ordinary bubbles and are extremely stable. Most bubbles quickly rise to the surface of a liquid and collapse, however, due to the very low buoyancy of ultra-fine bubbles, they will remain suspended in liquids for an extended period of time. Also, the surface area-to-volume ratio per mass is much higher compared to ordinary bubbles. In addition, the bubbles are believed to have negatively charged surface leading to higher capacity of carrying counter ion electrolytes and positively charged materials. Although the nature of ultra-fine bubbles are not fully understood, due to these extraordinary chemical and physical characteristics, they are currently used in the field of agriculture as promoters for plant growth, oyster sterilization and as cleansing agents in industrial and in the food market.

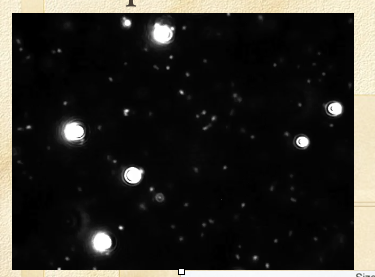

Ultra-fine bubbles (less than 1µmin diameter) visualized with laser scattering.

How are nanobubbles made?

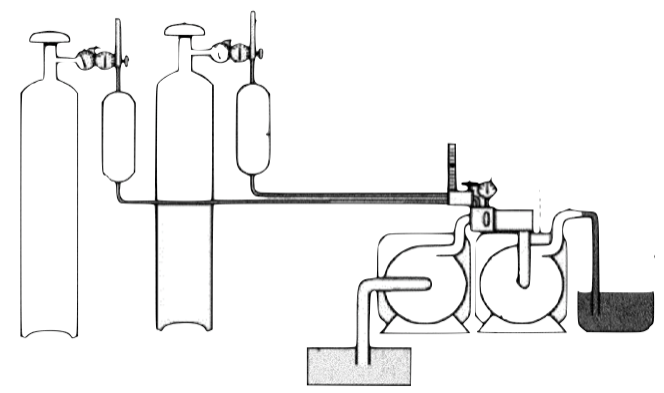

Conventional ultra-fine bubble generators are composed of pressure controlled chambers, high pressure air tanks, special nozzles and sophisticated circulation tubing systems. Liters and liters of liquid are required to generate sufficient amounts of bubbles. Large bubble generators can produce tons of nanobubble included wastewater solutions to eliminated bacteria, algae and fungi in dams and lakes. Such devices are frequently used to produce ultra-fine bubbles in massive volumes.

Ultra-fine bubbles. Large air compressors and circulating massive amounts of liquids are necessary to produce bubbles.

Our method of producing bubbles

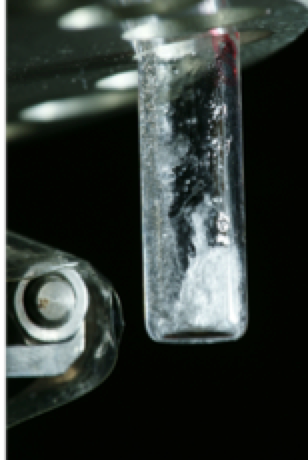

Super High Speed Vibration Bubbling (SHSVB) system is a patented technology developed by scientists at Fukuoka University School of Medicine in Japan. This revolutionary method enables ultra-fine bubbles to be produced in very small volumes (2-15ml) in a closed sterilized environment. The basic mechanism is simple. The container with a specific liquid is pressurized and shaken at super high speeds ranging from 6000 rpm to 10000 rpm. This results in production of highly concentrated and stable ultra-fine bubbles ranging from sizes of 50 to 500 nm. Any gas of choice can be pre-filled in the container to produce for example oxygen, hydrogen, argon loaded nanobubbles. This SHSVB system was first developed under the concept of investigating a possible use of ultra-fine bubbles for the medical field. Conventional bubble generators are unfit for evaluating multi-numbers of experiments with different conditions and materials. In addition, pharmaceutical materials are often expensive and cannot be obtained in massive volume. For example, evaluation of an antibody carrying ultra-fine bubble for oncology treatment purposes is not practical with conventional bubble generating methods and simply out of the question from a financial point of view. Why little research on the medical application of ultra-fine bubble, was in part due to the above reasons.

Small air tight pressurized container. The container is shaken at very high velocities horizontally and vertically.

High speed videos show violent turbulent flow within the custom made air tight container.